A Comparison:

Outside Frame vs the Tower of the NREL 5 MW Reference Turbine

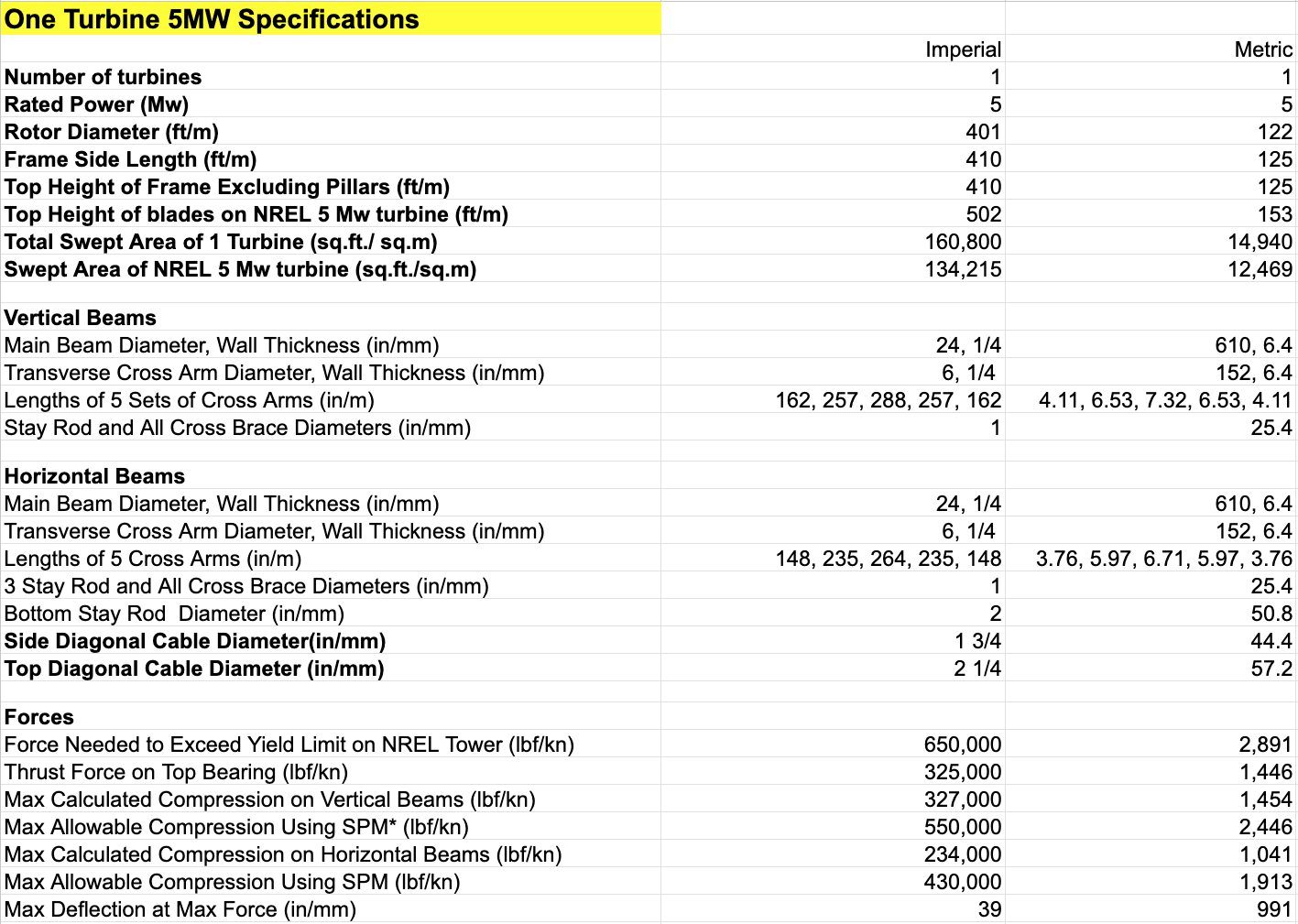

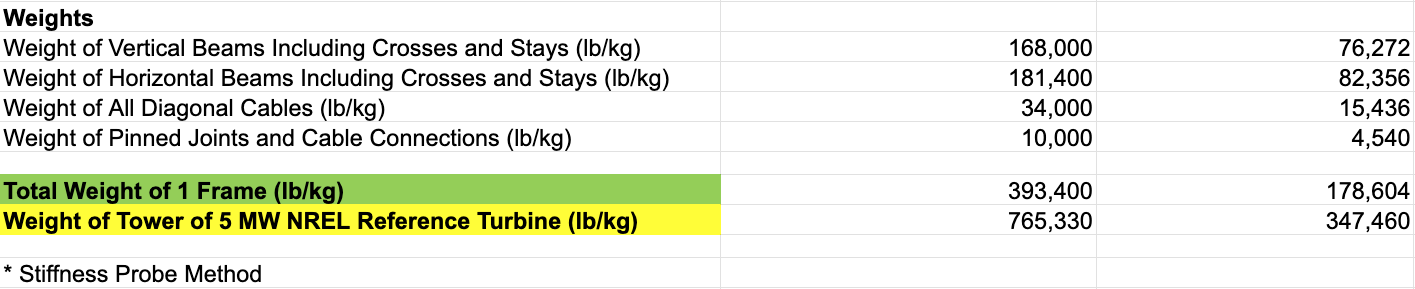

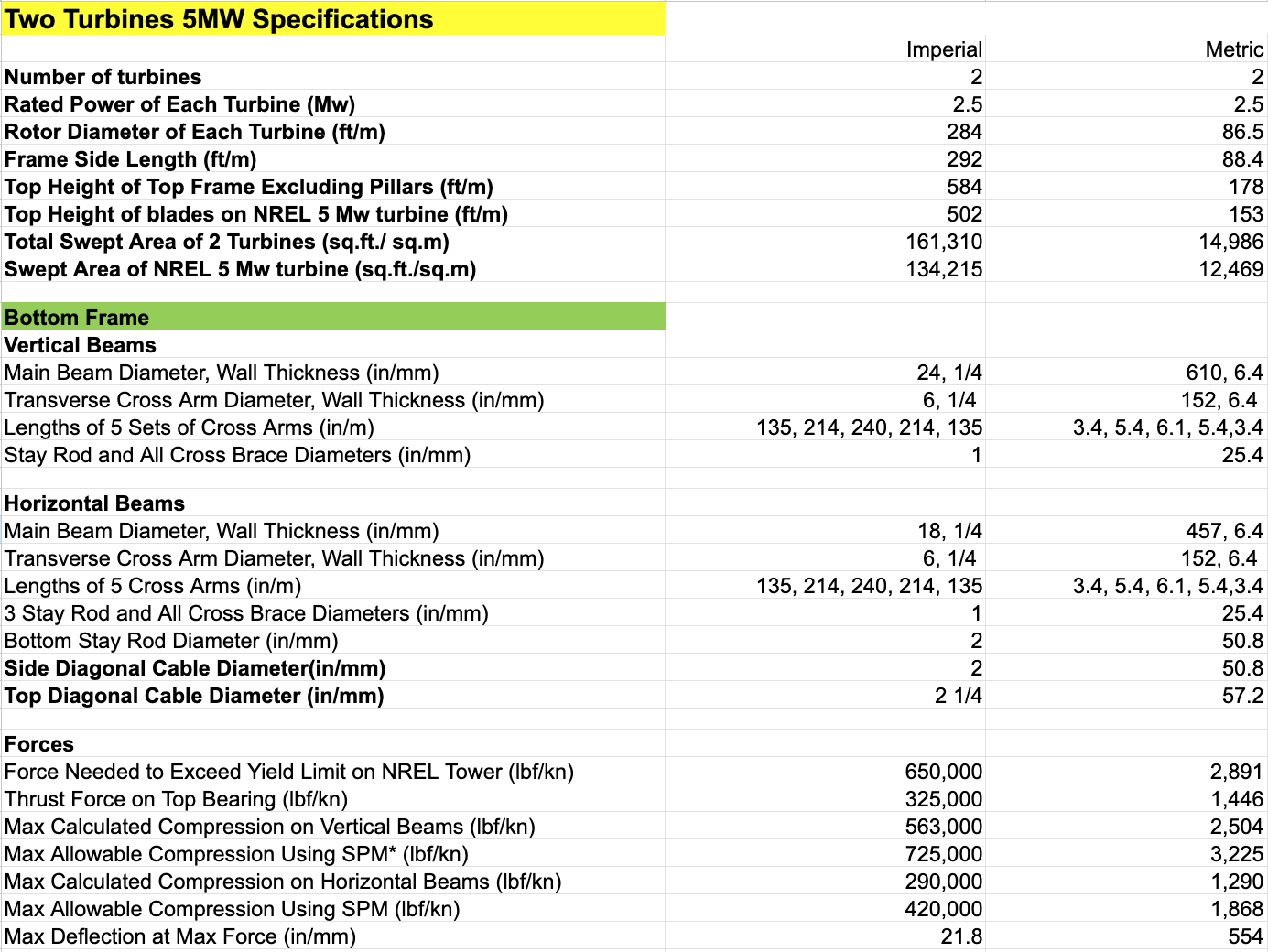

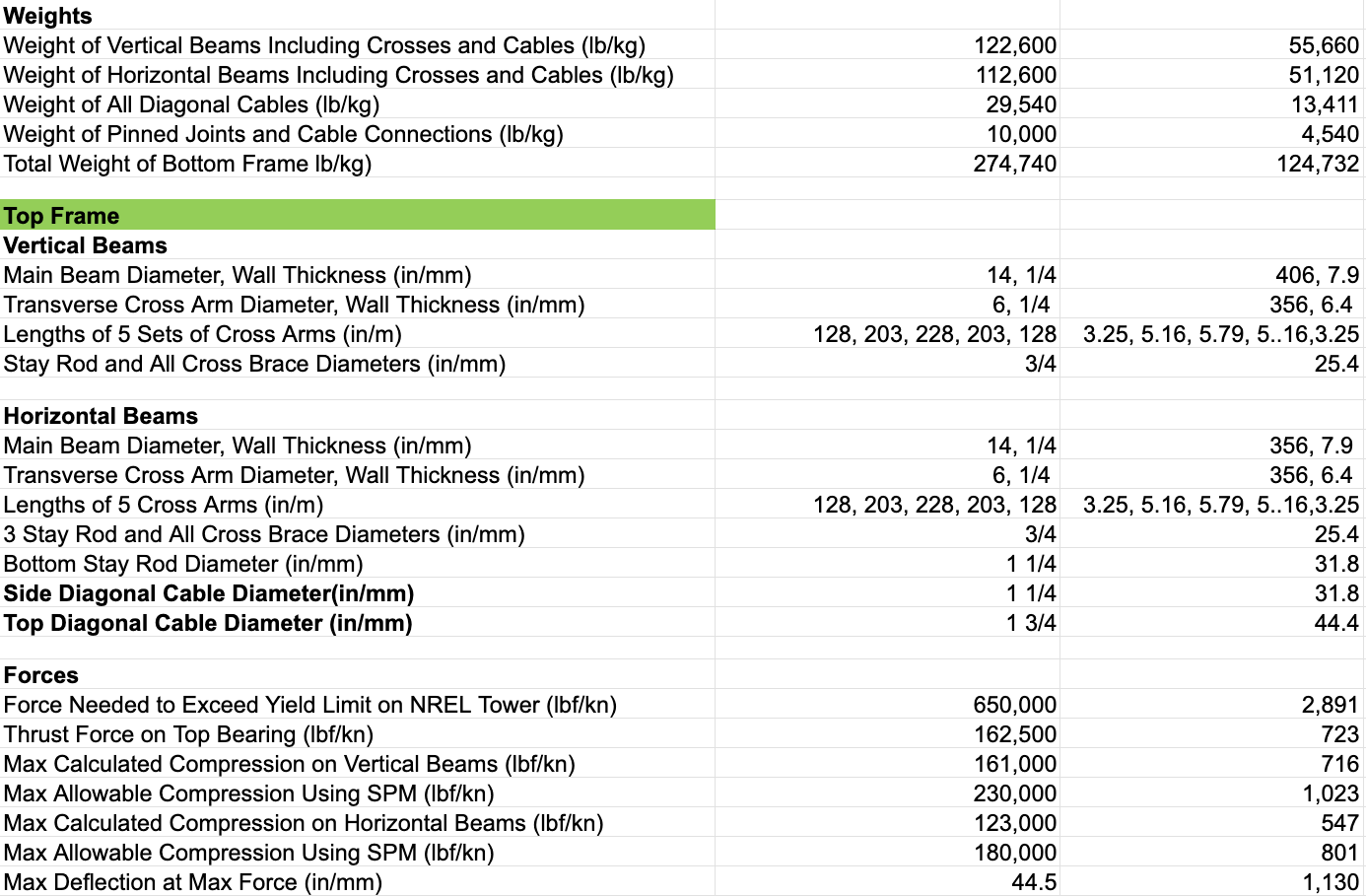

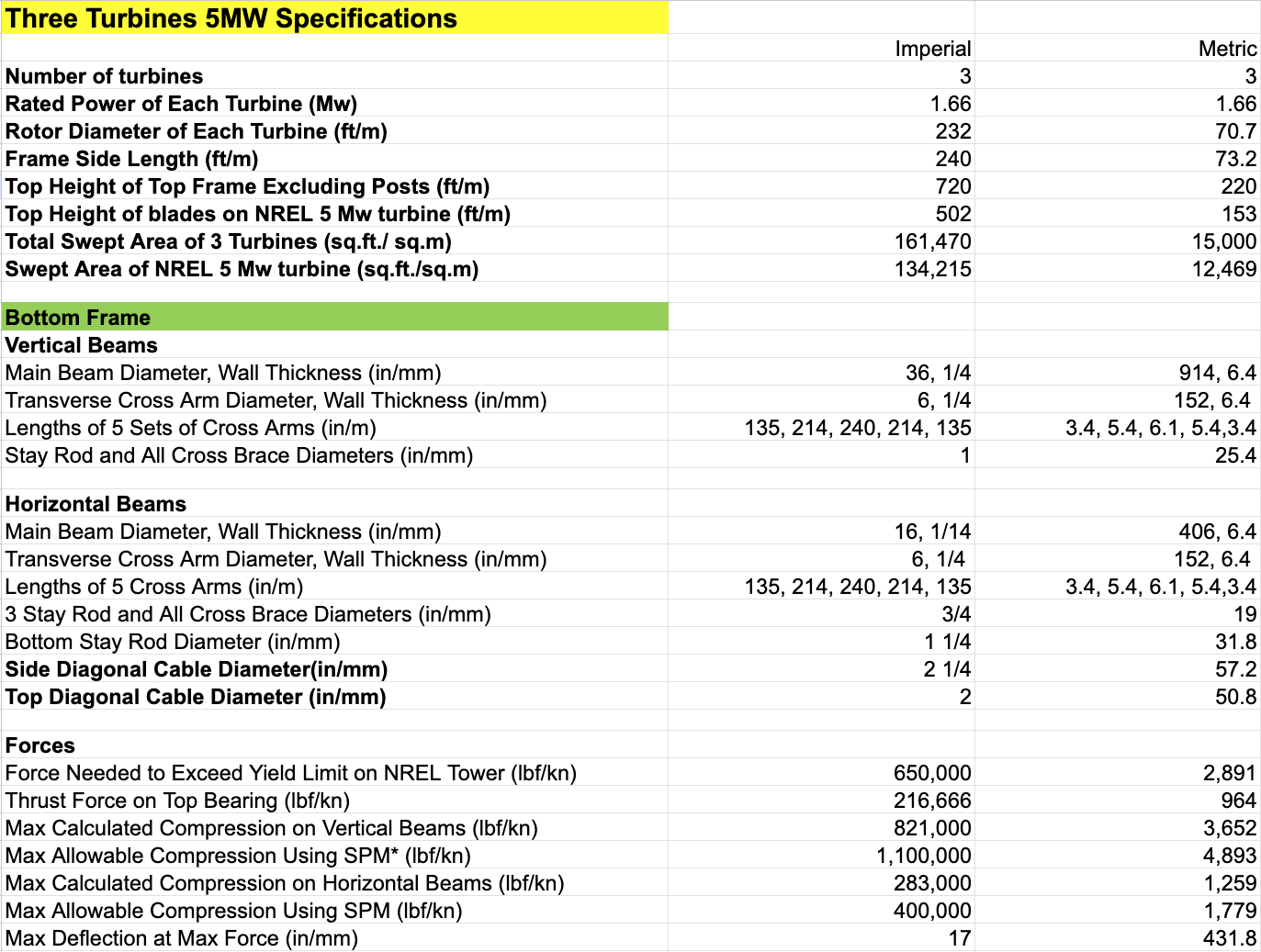

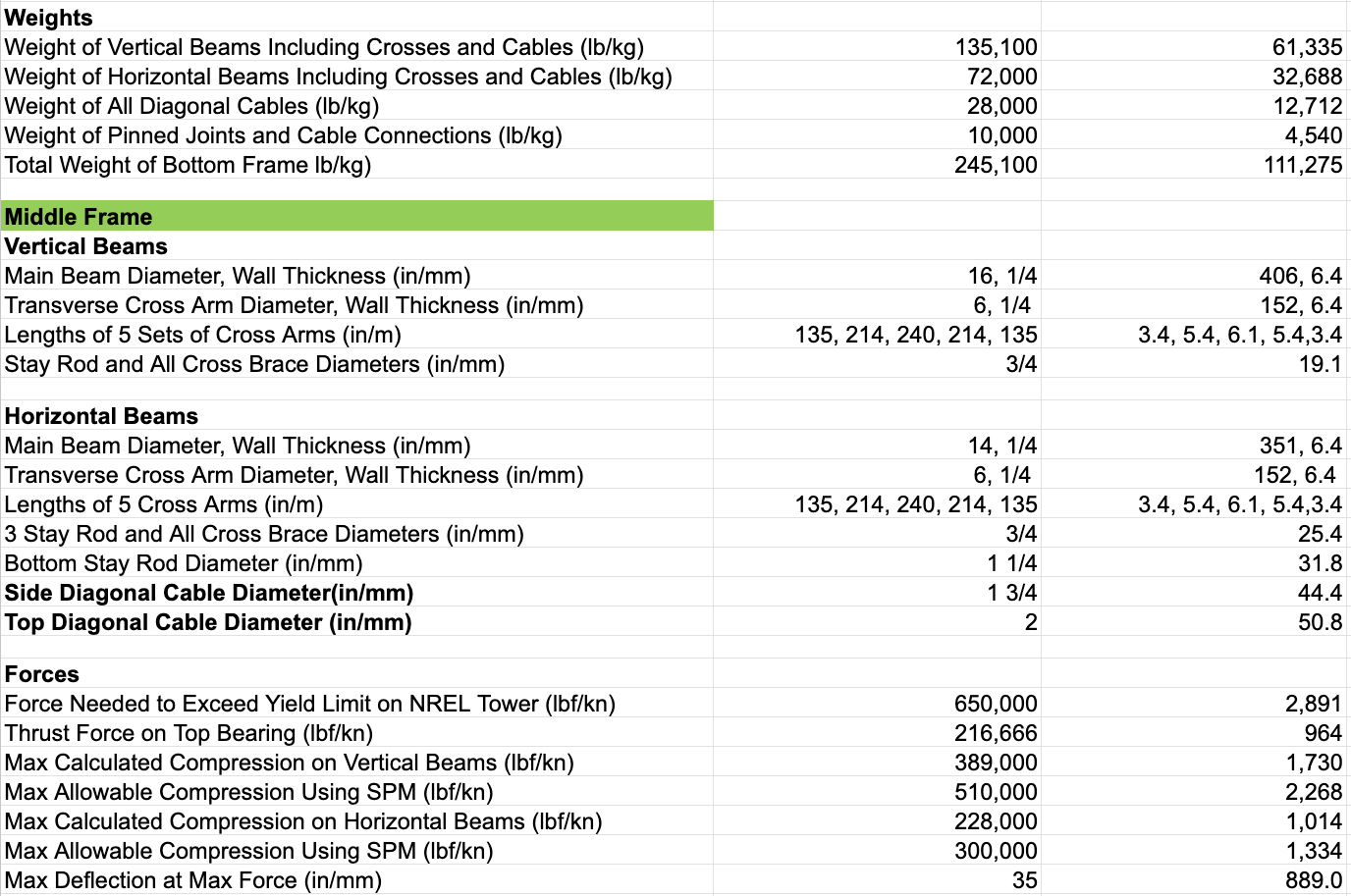

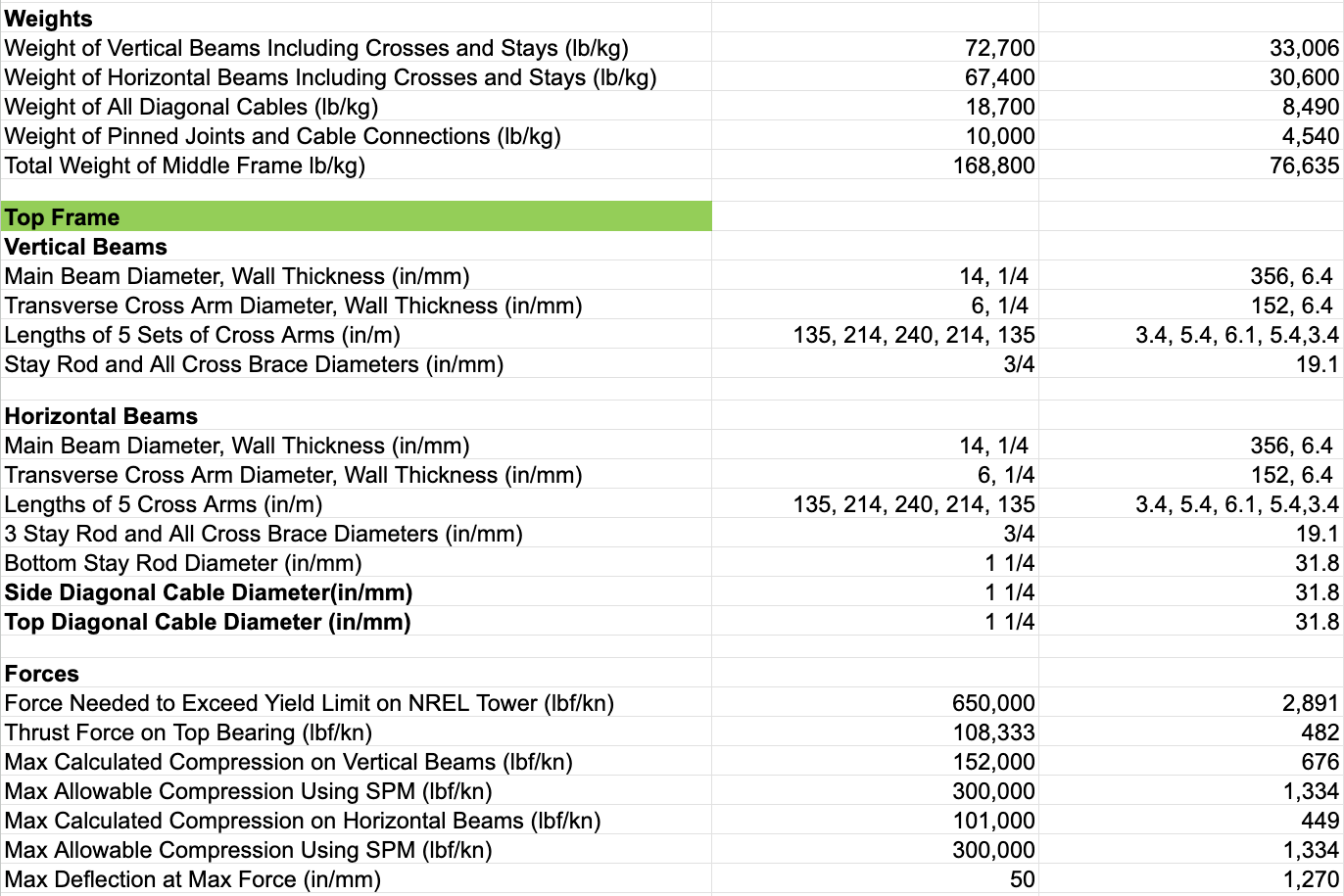

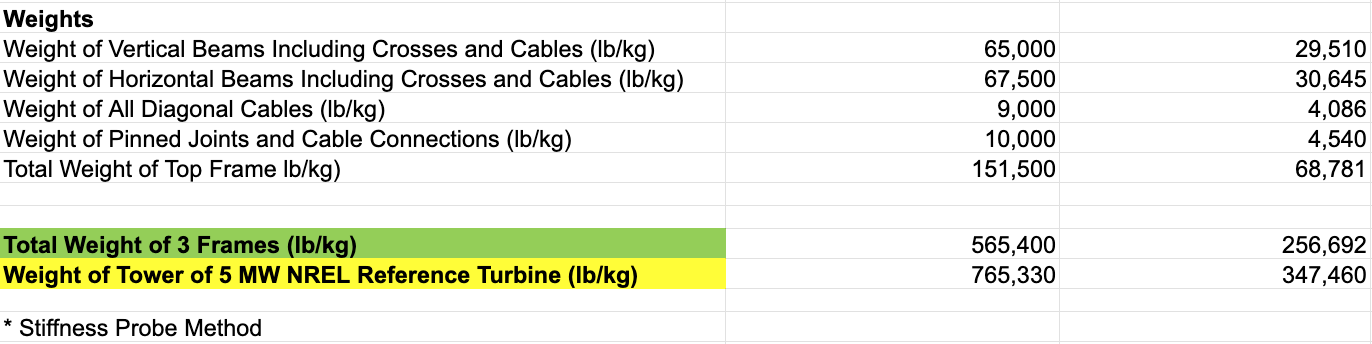

I analyzed the frames of three different 5 Mw wind turbine arrangements: the frame of one turbine alone; the frame of two turbines, one on top of each other; and the frame of three turbines, one on top of each other. I provided all the dimensions of the beams, crosses, stays, and diagonal cables used in the analysis. The analysis shows the rigidity of the frame and the weight of the steel needed to build it.

The following data from the NREL 5 Mw reference turbine was used to compare the Outside Frame of my design to the tower of the NREL turbine.

Height above ground 90m

Outside diameter at the bottom 6m

Material thickness at the bottom 0.027 m

Swept Area 12,469 m2

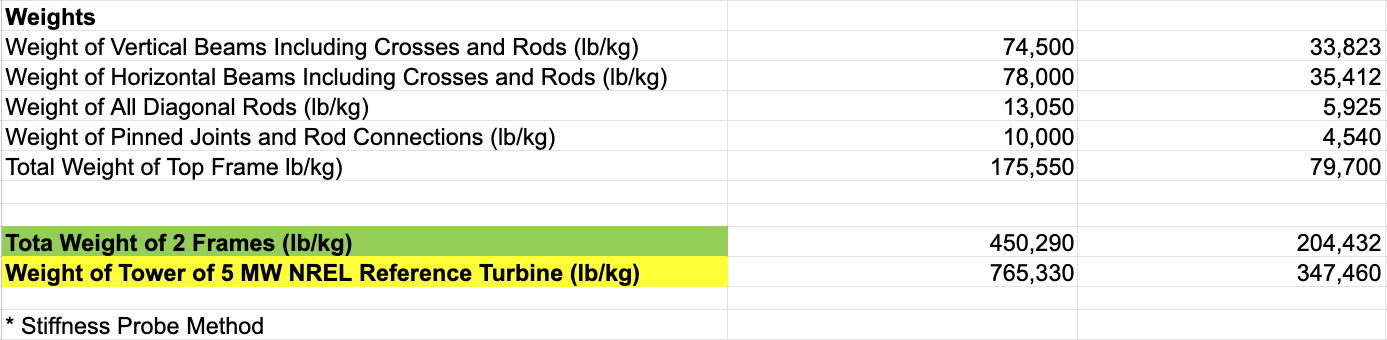

Weight of the turbine tower 347,460 Kg

Thrust at rated power 827 KN

Yield strength of AISI 1020 steel 350 MPA

Assumptions:

1. The thrust of the NREL turbine at rated power is given at 847 KN but I did a bit of reverse engineering and if I use the data above, the tower will exceed the yield limit of the steel if the thrust force at the top is larger than 2,890 KN. My assumption is that this force considers all relevant factors needed to prevent the failure of the tower. Therefore, I will use this 2,890 KN force on my 5 MW Outside Frame turbines.

2. A VAWT requires about 20% more swept area than a HAWT to produce a similar power curve. I do not have data from a 5 MW VAWT turbine so even though the blade aerodynamics improve as the blades get larger, I used the 20% increase or 15,000 m2 swept area for my calculations.

3. Four posts, one at each corner, support the four corners of the bottom cube at a site specific height. The weight of the posts is not included in the weight of the frame, just as the weight of the foundation is not included in the weight of the tower on a HAWT. Also, the generator, gearbox, electronics, bearing and brakes are mounted at ground level in the middle of the cube and have no influence on the frame.

4. I assume an H style VAWT would be contained inside the frame, but it is not restricted to this design. With a bit of imagination, almost any wind turbine could be installed inside the frame.

5. The SPM values of Pcr, calculated for all the stayed columns in the analysis are higher than the calculated compressions. This was done to add another level of confidence for these beams.

6. The parasitic drag produced by the stayed columns has not been included in the analysis. This drag force, if found significant, may be reduced by installing self-aligning fairings on the outside of each pipe or rod. These airfoil shaped fairings, made from thin metal or plastic, has proven to benefit the small aircraft and racing car market.

7. Wind shear has not been included, but its analysis would be required in a more detailed design of a commercial product.

Please go to the website’s ‘Analysis’ section for the data used in this comparison of the Outside Frame and the tower of the NREL 5 MW turbines.